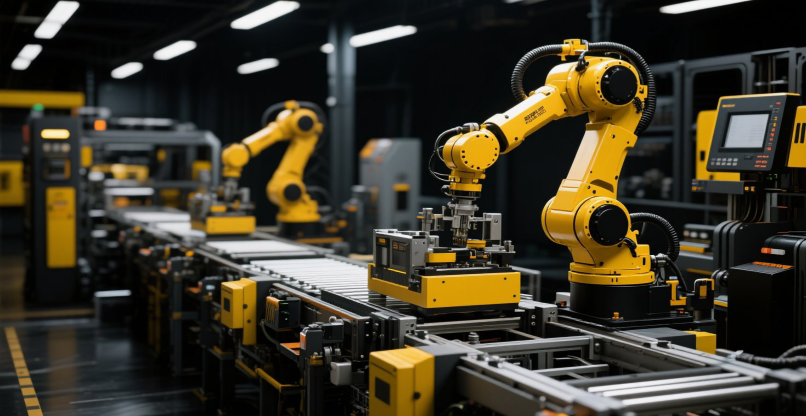

Automation Solutions Trusted by Global Automotive Leaders

FAPartsDirect.com is backed by extensive experience in automotive automation, serving top-tier brands such as CATL, BMW, and Tesla.

With deep expertise in EV battery lines, robotic welding, and assembly systems, we understand what true performance and reliability mean in automotive manufacturing.

• High-speed production lines with zero tolerance for downtime

• Harsh operating conditions including dust, vibration, and welding heat

• Increasing complexity driven by EV modular design and integration

• Pressure to reduce costs while boosting throughput and quality

| Category | Example Product | Use Case |

|---|---|---|

| Servo Motors & Drives | EtherCAT servo kits (e.g., Yaskawa, Siemens) | Robot axis motion, welding gun control, conveyor positioning |

| Pneumatic Cylinders | ISO15552 & guided types | Panel pressing, fixture movement |

| Industrial Robots | 6-axis or SCARA (KUKA, ABB, Fanuc) | Pick & place, bolt tightening, loading |

| Sensors | Vision systems, Proximity sensors, Laser sensors | Workpiece detection, precision positioning |

| PLC & HMI | XINJE / Siemens / Inovance | Line logic control, system monitoring |

• EV battery module assembly lines

• Welding & sealant application lines

• Interior & door panel installation systems

• Motor and gearbox assembly cells

• End-of-line testing stations

Partnered closely with BMW’s engineering team to develop a bespoke automation solution tailored to the plant’s specific production workflows and stringent quality requirements.

Integrated precision servo drive systems and industrial robots to facilitate synchronized, high-speed assembly operations across multiple stations.

Implemented advanced sensing and PLC control technologies to enable continuous real-time monitoring and data-driven process management.

Delivered comprehensive technical support throughout commissioning, fine-tuning, and operator training to ensure a smooth transition to full production.

Production efficiency and automation levels improved significantly, surpassing initial targets by more than 30%.

Process reliability and product consistency increased, contributing to a measurable rise in overall yield.

The solution’s compatibility and modular design support streamlined maintenance and future system expansions.

Project milestones were met on schedule, earning recognition from BMW’s management for effective collaboration and execution.

Proven Expertise: Decades of experience delivering automation solutions trusted by leading automotive manufacturers including CATL, Tesla, and BMW.

Reliable Components: All products are pre-qualified and field-tested for demanding automotive production environments.

Seamless Integration: Components compatible with major industrial brands such as SMC, Siemens, Omron, and Festo, ensuring smooth system interoperability.

Global Supply Chain: Efficient logistics with DDP terms available to over 50 countries, minimizing downtime and project delays.

Dedicated Technical Support: Around-the-clock engineering assistance to support project implementation, fine-tuning, and troubleshooting.

We understand your priorities: speed, stability, and system compatibility.

Please fill out the form below with your details and requirements, and our automotive automation expert will get back to you promptly.